This year, more than 50% of retail brands will invest in tools that allow them to sell anywhere. And for good reason: Nearly 3 in 4 customers use multiple channels to shop. Meanwhile, research shows that the opportunity cost of not adopting an omnichannel retail strategy could be as much as 10% in lost revenue. But this sales-boosting strategy also comes with a key challenge: channel customization, or meeting the bundling and packaging requirements of multiple retailers and channels.

In today’s omnichannel world, channel customization is about more than just having different packaging for e-commerce and providing bigger bundles for club stores. As retailers get more specific about branding, sustainability and other criteria, it’s not uncommon for each one to require different packaging. Sometimes this can involve newly engineered packaging or updated brand visuals; other times, it can mean repacking your product in different quantities. Special promotions can also require custom packaging like point-of-purchase (POP) displays.

Navigating these various packaging requirements can be challenging for even the savviest brand managers, and the cost only increases as you add more retailers to your roster. But losing your physical shelf space — and missing out on potential sales — is even more costly. This leaves brand managers with a tough question: How can they secure revenue from untapped channels without letting these packaging changes hurt their margins?

The Value of an Omnichannel Retail Strategy

In a recent survey, 46% of retailers say they plan to increase their investment in digital sales channels, including innovative avenues like livestream selling and custom mobile apps. But in today’s digital era, the battle for physical shelf space is also more heated than ever. In a Shopify study, 82% of businesses said physical stores will continue to play an important role in future commerce growth. Many retailers now generate equal sales from brick-and-mortar and e-commerce purchases, and the majority of shoppers prefer to blend in-store and online when making purchasing decisions. In a world where shopping can happen anywhere, brand managers are getting serious about reaching their customers wherever they are — both online and offline.

Today’s brands are selling on more channels than ever before, with the potential for major benefits including:

- Greater product distribution as more retailers sell your product(s)

- Differentiated offerings and margins between channels

- The ability to align your marketing and sales strategy with the customer’s journey

- More e-commerce business, both direct and via retailers

- An advantage over competitors that don’t adopt an omnichannel strategy

The bottom line: More channels means more opportunities for sales

As far back as 2015, research already demonstrated that selling on more than one channel increased revenue. Statistics from Google show that omnichannel shoppers have a 30% higher lifetime value than those who only make purchases through a single channel. Since then, the number of available sales channels — and the potential upside for brands that invest in an omnichannel approach — has only grown. In 2023, selling in multiple channels has gone from a “nice to have” to a “must-have” retail brand strategy.

Selling your product in more places is now a no-brainer for retail brand managers. But it also raises packaging challenges that can prevent brands from expanding into new channels and, in some cases, new geographic markets.

Key Packaging Challenges for Brands Expanding into Multiple Retail Channels

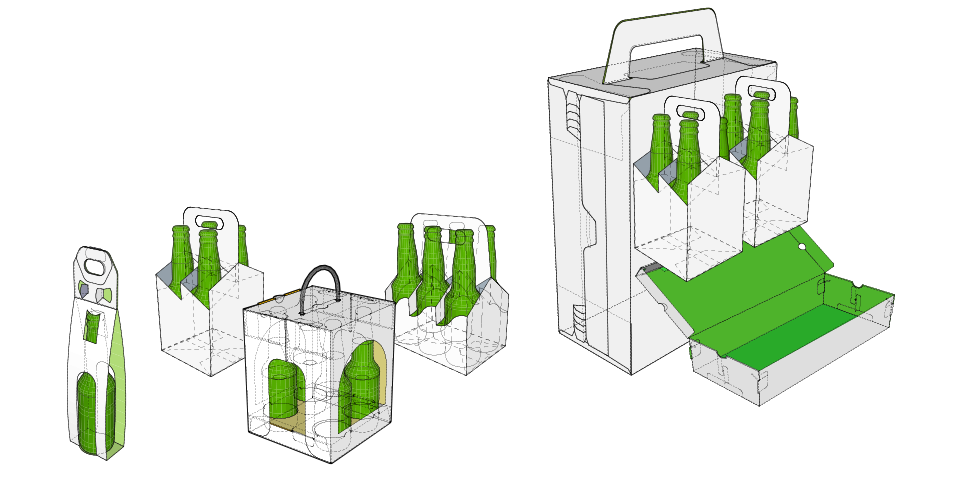

As your brand’s retail channels expand, so does the possibility of increased packaging complexity. Many retailers have specific sustainability and branding requirements, which could require a newly engineered version of your existing packaging. Special promotions — a major opportunity for boosting sales — often require customized packaging. And then there’s item count: Depending on your product category, retailers could choose to stock your items only if they’re bundled in a particular quantity.

Custom bundles are especially common with club stores, but they can also come into play when packaging your product for e-commerce or an in-store promotion. Bundling requirements can also vary from one country to the next, as was the case with a European personal-care brand that needed to repack its items into smaller sets for U.S. retailers. (Read the case study here.)

Managing costs and minimizing risk

It can be challenging for brands to accommodate packaging customizations while maintaining their bottom line. Handling these customizations in-house requires packaging equipment and labor — both of which can quickly erode a retail brand’s margin. The more packaging complexity, the more cost.

The Benefits of a Packaging Partner for Channel Customization

Rather than run the risk of high costs and significant investments in equipment and labor, more brands than ever are partnering with Victory Packaging for channel customization. We’ve invested heavily in specialized equipment, materials, processes and expertise so that you can meet retailers’ requirements without shrinking your margins. We reduce your risk and optimize your packaging costs, supporting you as you expand your brand’s retail footprint across physical and online stores.

Proven packaging engineering expertise

Trust Victory Packaging to design, source and manufacture packaging that meets each channel retailer’s specifications. That includes sustainable packaging materials, which are becoming increasingly in demand as both consumers and retailers prioritize a low carbon footprint.

With decades of specialized expertise, our engineers have a proven track record for designing packaging solutions that protect your product, reflect your brand and meet the unique needs of retailers. We understand the requirements of large brands in the market, using this expertise to move quickly on your behalf. We also have in-depth experience with e-commerce packaging, including strategies for reducing damage throughout the shipping process. And no matter your retailer’s requirements, we engineer packaging to meet all specifications while optimizing your cost.

Specialized kitting and assembly capabilities

Victory Packaging knows design and engineering. But we’re also equipped to assemble your product — and deliver it on time to its destination. By partnering with our experts for product kitting, assembly and/or co-packing, you can reduce your reliance on costly in-house labor and ensure you get retailers the customized bundles they need, exactly when they need them.

Our experts can spearhead your entire packaging operations, whether you require kitting — which involves putting items together, with your product added later — or assembling your products into a shipper or display vehicle. Our extensive supply chain footprint allows us to provide co-packing services inside our warehouses, where we reduce your costs by leveraging proven processes, an expert team and streamlined automation strategies. We’re also equipped to manage your packaging processes at your own facility or a convenient third-party facility.

Victory Packaging’s kitting and assembly capabilities create increased efficiencies, reduce your packaging labor costs and support you as you expand into more retail channels — no matter their packaging requirements.

Unlock the Power of Omnichannel Retail Today

From sustainable packaging materials to custom bundles, retailer requirements can make it challenging for brands to adopt a true omnichannel sales strategy. With Victory Packaging’s channel customization solutions, brands no longer have to sacrifice profit margins to fulfill retail packaging requirements. Get in touch with us today to explore how our packaging design, engineering, kitting and assembly capabilities can help you expand into new markets and reap all the benefits of selling on more channels and in more retailers.