According to the Harvard Business Review, more than 30,000 new products are launched in the U.S. each year—each requiring packaging in some way, shape or form. Although packaging strategies are as varied as the sheer scope of product types available to consumers, that doesn’t mean there isn’t some common ground. If you’re looking to launch a new product and need packaging or simply want to improve your existing strategy, use these top factors of high-quality packaging to ensure your product is positioned for success.

Customized

It’s no surprise that in today’s digital world, consumers are flocking to customized, personalized experiences. As a result, leading brands are customizing their packaging—either to individual consumers or campaigns, or to the unique needs and personality of their product. (Check out Lay’s recently launched ‘Everyday Smilers’ campaign for the latest example of a major brand taking customized packaging to new heights.)

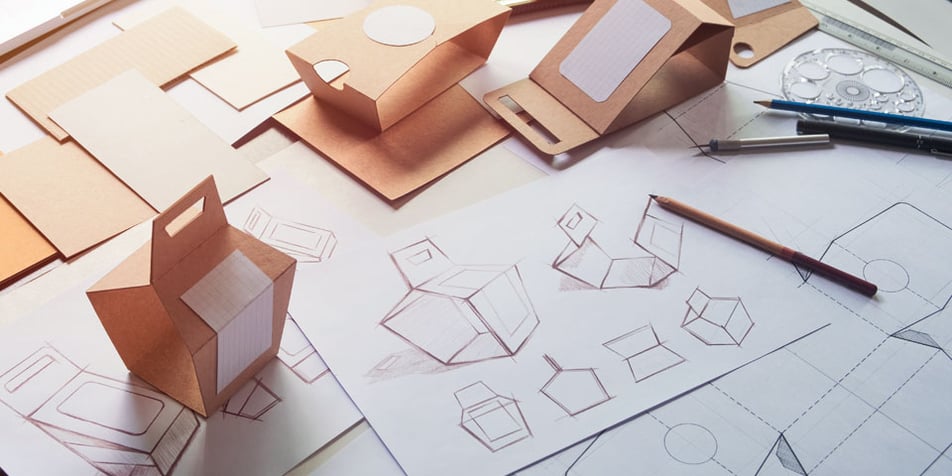

If you’re serious about high-quality packaging, choose a partner who has the capability to deliver customized solutions. A packaging engineer, for example, can design packaging based on particular specifications and other unique requirements. Through the process of developing customized packaging, your partner can also help you optimize costs and minimize material waste—both factors critical to your packaging bottom line.

Tested

Tested

Innovative packaging can capture consumer attention and set your brand apart on a crowded shelf. But any high-quality, “outside of the box” packaging in use today had to go through rigorous testing to get there. Simply put, when it comes to keeping your product damage-free, it’s best to work out the kinks of a new design in a lab—not as a result of negative customer reviews.

Be sure to work with a packaging engineer who will test your packaging in a lab equipped with the advanced technology needed to ensure its performance. The most qualified engineering teams will also have ISTA-trained technicians who conduct in-depth testing to ensure your packaging meets all relevant industry standards and product-specific requirements. If your brand is serious about better packaging, it’s critical to take the time to test it carefully before it hits the market so that you can either make adjustments or have full confidence that your product’s packaging delivers an optimal experience without the pitfalls of overdesign.

Branded

Packaging offers an undeniable opportunity to showcase your brand’s logo, color palette, personality and values. Along with the rise of customized packaging, brands are getting creative about using every part of their packaging to showcase their style. In the colorful world of craft beer packaging, for example, brewers are going way beyond labels alone, tapping into the power of branded beer trays, can ends, mother cartons and more.

Don’t let branding opportunities go untapped by limiting your approach to a mere logo on your box or pouch. Get creative with branded stretch films, tertiary packaging and beyond. By working with an experienced packaging solutions partner, you can ensure your company utilizes every inch of packaging real estate to ingrain your brand into the hearts and minds of consumers.

Sustainable

For today’s consumers, sustainability is becoming a key decision-making factor. For tomorrow’s consumers, all signs show your packaging’s carbon footprint will hold even more weight. The bottom line? If you’re not thinking about sustainability when you launch or update your packaging, you’re missing a critical opportunity for future-proofing your brand.

Trader Joe’s has pledged to cut one million pounds of single-use plastic from its stores. Nestle has quickly followed suit. And now, the rise of reusable packaging is making eco-friendly options the new norm. When designing your packaging, be sure to account for its carbon footprint. Does your design involve material waste? Are you relying only on single-use plastic, or is there another material that could deliver the same protection with less environmental impact? How can you incorporate new materials or designs such as zippers to give your packaging a reusable quality? And although the supply chain is often overlooked, don’t forget to analyze how much energy is used in getting your packaging from design to your customer’s door.

By working with a custom packaging solutions partner who handles all aspects of your packaging, you can identify areas for sustainability across your supply chain. This is yet another way that leading brands are using packaging to satisfy evolving consumer preferences and enhance their bottom line.

Whether you’re launching a new product or revamping your existing packaging, use these four best practices to ensure your products are damage-free, appealing to consumers and reflecting the need for sustainable packaging solutions. Contact us today to see how our experts can help you achieve the high-quality packaging your products and your customers deserve.