In recent years, nearshoring has emerged as a prominent global trend. This surge can be explained by many global events that make companies take the strategic step of relocating their business operations to neighboring countries. In the US, nearshoring is gaining traction as a larger number of businesses are shifting operations from APAC countries to Mexico — a move designed to reduce risk amid significant global volatility.

According to a recent Morgan Stanley study, new nearshoring investments could reach about $46 billion over the next five years, helping to boost Mexico's annual GDP growth to about 3% between 2025 and 2027. This has the potential to accelerate the growth of Mexico’s manufacturing exports to the U.S. from $455 billion to an estimated $609 billion over the next five years, boosting Mexico's economy while delivering benefits to US companies.

Nearshoring is often credited with helping to reduce geopolitical risks by establishing closer ties with neighboring countries. It also offers compelling advantages for businesses equipped with the right strategy, such as enabling significant shipping and transportation cost savings due to the geographic proximity between manufacturing hubs and consumer markets. Nearshoring can also help companies minimize carbon emissions associated with long-haul transportation routes.

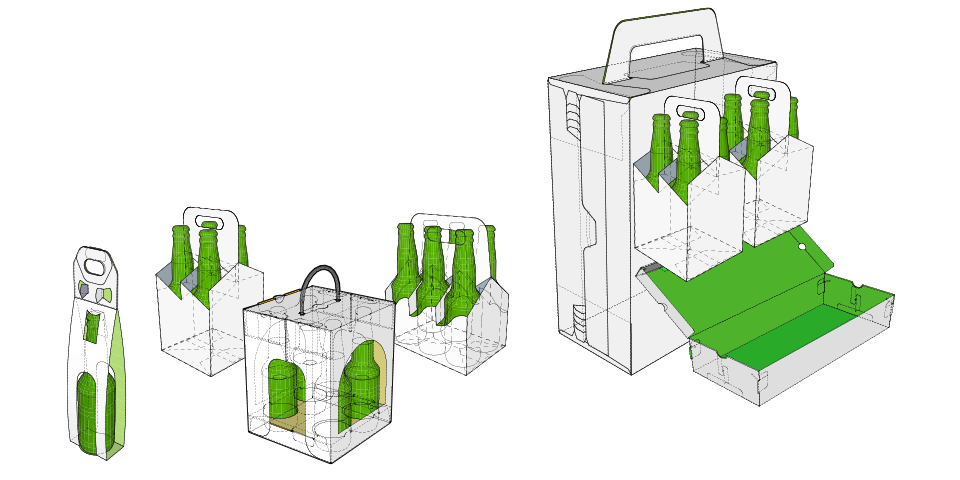

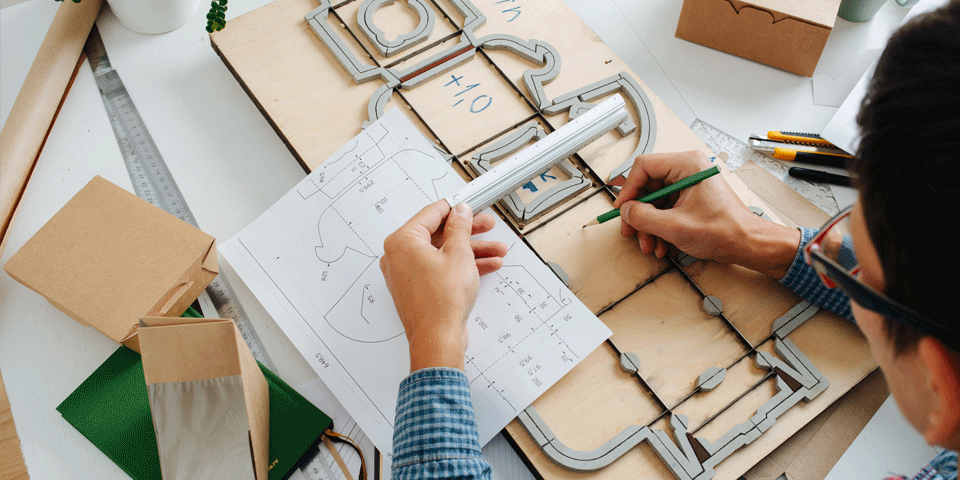

But in spite of these promising opportunities, nearshoring also brings challenges — particularly in the packaging supply chain. Maintaining consistency, quality and continuity across operations in Mexico and the US is critical. Addressing these challenges requires partnering with a packaging company that brings expertise and resources on both sides of the border.